IPFL, where advanced 3D printing and precise plastic machining come together to serve avionics, aerospace, and electronics component manufacturers. Discover how our diverse printing technologies can transform the design, functionality, and manufacturing of crucial avionic components, enhancing both performance and cost efficiency.

The avionics industry is integral to the aerospace sector, focusing on electronic systems used in aircraft, satellites, and spacecraft. This field is characterized by rapid technological advancements and stringent regulatory standards. Key challenges include the need for high reliability, compliance with international safety standards, and the continuous push for lighter, more efficient systems. Innovations in 3D printing offer transformative solutions to these challenges, providing ways to manufacture lighter, more complex components rapidly and cost-effectively.

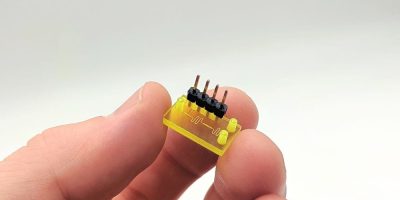

Micro 3D printing excels in creating ultra-precise components crucial for sensitive avionic systems. Its high resolution is perfect for developing micro-scale actuators, sensors, and connectors essential in flight control systems, navigation, and communications. These components benefit from the accuracy and complexity that micro 3D printing can achieve, enhancing system reliability and performance in the demanding aerospace environment.

HP MJF is tailored for producing robust components with fine detail and excellent mechanical properties using materials like PA12 nylon. Ideal for parts exposed to high stress and wear, such as engine controls and housing for critical sensors, MJF’s precision and durability make it indispensable for safety-critical avionic applications.

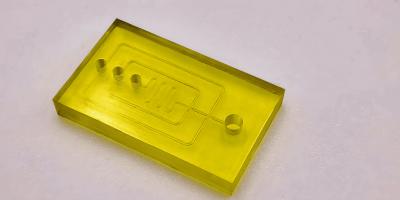

SLA’s ability to produce clear, high-quality surfaces with intricate details makes it ideal for optical components in avionics, such as lens covers and light guides used in cockpit displays and external lighting systems. These components benefit from SLA’s high resolution and the ability to polish finished parts to optical clarity, ensuring precise operation in critical applications.

FDM’s adaptability in handling high-performance materials like aerospace-approved Ultem supports the creation of durable parts capable of withstanding extreme temperatures and chemical exposure. This technology is particularly suited for fabricating components located in engine areas and other high-stress environments within the aircraft.

PolyJet technology is exceptional for its precision in multi-material printing, allowing for the production of parts with varying degrees of flexibility and rigidity within a single component. This capability is critical for creating customizable seals, gaskets, and vibration-dampening components, which contribute to enhanced functionality and comfort in aircraft operation.

Micro 3D printing is pivotal in avionics for its unmatched precision and ability to fabricate micro-scale components crucial for advanced aerospace applications. It enables the production of finely detailed components that traditional manufacturing cannot achieve, providing better performance, integration, and miniaturization of avionic systems.

At IPFL, we are committed to pushing the boundaries of what’s possible with 3D printing technologies to meet and exceed the stringent demands of the aerospace and electronics industries. Our expert team is ready to assist you in discovering how our tailored 3D printing solutions can revolutionize your production processes and elevate your product performance. Contact us today to learn more about our capabilities and how we can support your manufacturing goals.