Introduction

3D printing has revolutionized various aspects of Formula 1 (F1) wind tunnel testing by providing rapid prototyping capabilities. This allows teams to quickly and cost-effectively produce complex aerodynamic components. Utilising Stratasys Polyjet technology at IPFL, the industry expedites the development cycle.

Importance of Wind Tunnel Testing in F1

Wind tunnel testing in Formula 1 (F1) is crucial for car development. The primary goal is to optimize vehicle aerodynamics, ensuring maximum downforce and minimal drag, which enhances speed, stability, and handling.

Types of Wind Tunnels

- Full-scale Wind Tunnels: These accommodate a full-sized car and are used for final testing and validation of aerodynamic concepts.

- Scale-model Wind Tunnels: Typically use a 50% or 60% scale model of the car. These are more cost-effective and allow for more frequent testing.

Examples of 3D Printed F1 Components

- Winglets and Endplates: Highly complex parts benefiting from the design flexibility of 3D printing.

- Brake Ducts: Customized brake cooling solutions can be rapidly prototyped and tested.

- Internal Aerodynamic Devices: Manage airflow within the car’s bodywork, quickly produced and refined.

Wind Tunnel Testing Process

- Model Preparation: Scale models or full-sized cars are prepared with detailed aerodynamic features such as wings, diffusers, and bodywork.

- Instrumentation: The car or model is equipped with sensors and pressure taps to collect data on airflow, pressure distribution, and aerodynamic forces.

- Testing Setup: The car is placed in the wind tunnel, which simulates the aerodynamic conditions the car will face on the track. The wind speed can be adjusted to match different racing conditions.

- Data Collection: During testing, engineers collect data on lift, drag, and airflow patterns. Smoke or laser-based techniques may be used to visualize airflow.

- Analysis and Iteration: The data is analyzed to understand the car’s aerodynamic performance. Engineers then make iterative changes to the design, such as adjusting the angle of wings or modifying bodywork and re-testing to measure improvements.

Technological Integration

Wind tunnel testing is complemented by Computational Fluid Dynamics (CFD) simulations. CFD allows teams to run virtual aerodynamic tests, reducing the dependency on physical wind tunnel testing and accelerating the development process.

Importance of Aerodynamics in F1

Aerodynamics play a critical role in F1, influencing the car’s performance in terms of speed, fuel efficiency, and tyre wear. Wind tunnel testing helps teams find the optimal aerodynamic setup for various tracks, giving them a competitive edge.

3D Printing in F1 Wind Tunnel Testing

Rapid Prototyping

- Speed: 3D printing significantly reduces the time required to produce scale models and components. What traditionally took weeks can now be done in days or even hours.

- Iteration: Engineers can quickly iterate on designs, printing multiple versions of a component to test and refine aerodynamic properties.

Complex Geometries

- Design Freedom: 3D printing allows for the creation of complex geometries that are difficult or impossible to produce with traditional manufacturing methods.

- Integrated Features: Components can be printed with integrated features such as internal channels for cooling or optimized structural elements.

Cost Efficiency

- Material Savings: 3D printing is more material-efficient, reducing costs.

- Reduced Tooling Costs: No need for expensive moulds or specialized tooling, making it economical to produce small batches or one-off parts.

Customization and Flexibility

- Tailored Components: Teams can customize parts for specific testing scenarios or track conditions.

- On-Demand Production: Parts can be printed on-demand, reducing the need for large inventories and allowing for quick changes during the testing phase.

Enhanced Data Collection

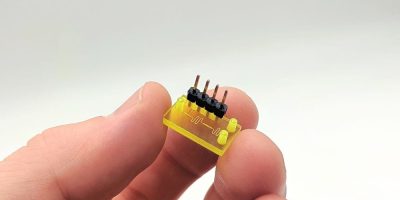

- Sensor Integration: 3D printed models can incorporate cavities and channels for sensors and instrumentation, allowing for more precise data collection.

- Fine-tuning: Engineers can print models with slight variations in design to fine-tune aerodynamic performance based on real-time data.

Material Innovation

- Advanced Materials: 3D printing uses high-performance materials that can mimic the properties of carbon fibre and other composites used in actual race cars.

- Testing Different Materials: Teams can experiment with different materials to see how they affect aerodynamic performance and structural integrity.

Full-scale and Scale Models

- Scale Models: 3D printing allows for precise and accurate scale models that replicate the full-scale car’s aerodynamic characteristics.

- Full-scale Components: Some full-scale parts are also 3D printed for final validation, ensuring that the final product matches the tested models.

Integration with CFD

- Complementary Tools: 3D printing works alongside CFD simulations. Initial designs can be tested virtually with CFD, and promising designs are then printed for physical validation.

- Hybrid Testing: Combining CFD and wind tunnel testing with 3D printed parts allows for a more comprehensive understanding of aerodynamic performance.

Stratasys PolyJet Technology in F1 Wind Tunnel Testing

Key Features of Stratasys PolyJet Technology

- High Resolution: PolyJet printers can produce parts with layer resolutions as fine as 14 microns, providing exceptional detail and accuracy.

- Multi-Material Printing: Allows for the simultaneous printing of multiple materials in a single build.

- Smooth Surface Finish: Produces parts with smooth surfaces straight out of the printer, reducing the need for post-processing.

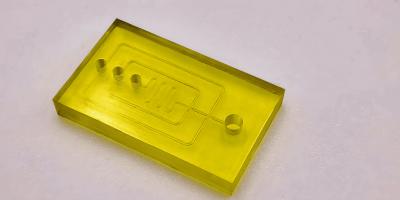

- Colour and Transparency: Can print in a wide range of colours and even transparent materials.

Applications in F1 Wind Tunnel Testing

- Aerodynamic Models: PolyJet technology is used to create highly detailed scale models of F1 cars for wind tunnel testing.

- Rapid Prototyping: Engineers can quickly iterate on designs by printing multiple versions of a component and testing them in the wind tunnel.

- Functional Testing: Multi-material parts allow teams to test components that combine flexible and rigid elements.

- Component Validation: Some full-scale aerodynamic components can be produced with PolyJet technology for final validation.

- Simulation and Visualization: Transparent and coloured materials allow for better visualization of internal flows and aerodynamics.

Heritage of IPFL with PolyJet Technology

IPFL has a rich heritage in 3D printing, being one of the first to adopt PolyJet technology 21 years ago. Since then, IPFL has continuously offered PolyJet 3D printing services, supporting the motorsport industry with cutting-edge solutions. This long-standing experience ensures that clients benefit from extensive expertise and reliable service in producing high-quality, precise components for aerodynamic testing.

Benefits of Using Stratasys PolyJet in F1

- Speed and Efficiency: Quick turnaround times from design to physical part enable faster development cycles.

- Precision and Accuracy: High-resolution printing ensures that even the smallest aerodynamic details are captured accurately.

- Versatility: The ability to print in multiple materials and colours provides greater flexibility in testing and visualization.

- Reduced Costs: Lower production costs for prototypes and small batches make it economically viable to test numerous iterations.

Conclusion

Stratasys PolyJet technology offers significant advantages for F1 wind tunnel testing, providing high precision, multi-material capabilities, and smooth surface finishes. These features enable rapid prototyping, accurate aerodynamic modelling, and efficient component validation, ultimately contributing to the development of high-performance F1 cars. IPFL’s 21 years of experience with PolyJet technology further ensures top-quality service and expertise, making them a trusted partner in the motorsport industry.