In the rapidly evolving world of micro-manufacturing, precision and versatility are paramount, especially for Microfluidic Embedded Electronics Manufacturing. At IPFL, we continually push the boundaries of innovation to meet the needs of industries demanding high-performance components with micron-level accuracy. A prime example of our capabilities can be seen in our recent project, where we developed a sophisticated component integrating embedded electronics within a microfluidic system using advanced micro 3D printing technologies.

This project required us to connect two microfluidic bioreactors using embedded electronics. The Microfluidic Embedded Electronics Manufacturing solution needed to be both mechanically robust and chemically compatible while maintaining exceptionally tight tolerances and intricate geometries. Traditional manufacturing methods often fall short when working with components on this scale, especially when combining materials like copper powder and specialized bio-resins.

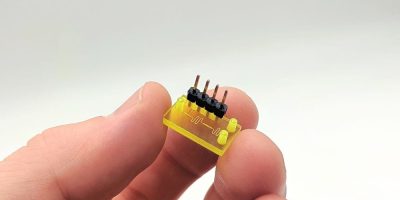

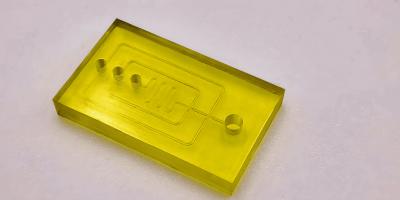

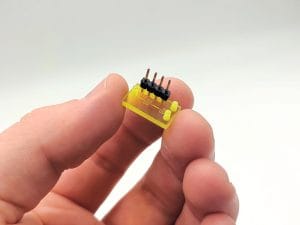

Utilizing our 10µm and 2µm resolution Projection Micro Stereolithography (PµSL) systems from Boston Micro Fabrication (BMF), we produced an intricate connector that seamlessly integrated with the bioreactors. Our micro 3D printing technology enabled us to achieve the required accuracy and complexity that would be impossible with conventional methods.

The key innovation was the infusion of copper powder within a BIO resin matrix, allowing for conductivity and compatibility with the microfluidic environment. This material combination facilitated a perfect blend of mechanical strength and electrical performance, enabling the successful connection of electronic sensors to monitor and control the fluidic flow within the system.

Our expertise spans beyond just micro 3D printing. IPFL has a comprehensive range of manufacturing capabilities, including CNC machining, SLA high-resolution printing, and multi-material production methods. This versatility enables us to produce bespoke components tailored to the unique requirements of every project, whether it’s for the medical, aerospace, or microelectronics industries.

For this project, the application of micro 3D printing at such fine resolutions ensured every minute feature, channel, and pathway was accurately reproduced, delivering a component with unparalleled precision and consistency.

Our in-house BMF micro 3D printing systems, capable of 10µm and 2µm resolution, place us at the forefront of micro-manufacturing technology. These systems enable us to offer exceptional geometrical intricacy and high-quality surface finishes for components that demand the highest level of detail. By leveraging these advanced technologies, we help our clients overcome complex design challenges and bring their most ambitious projects to life.

Projects like this illustrate how IPFL continues to advance the applications of micro-manufacturing. Our team’s ability to integrate novel materials, advanced electronics, and complex fluidic designs demonstrates our commitment to pushing the boundaries of what is possible in precision engineering.

Whether it’s microfluidics, connectors, or other micro-scale components, IPFL is your trusted partner for high-quality, precision-engineered solutions.

For more information on our micro 3D printing services and how we can support your next project, please reach out to us at sales@ipfl.co.uk or visit our website at www.ipfl.co.uk