Microneedles are gaining traction as a means to enhance transdermal vaccine delivery by creating tiny pores in the skin, improving permeability, and reducing patient discomfort.

This method of vaccine delivery works to stimulate antigen-presenting cells (APCs), particularly Langerhans cells in the epidermis and dermal dendritic cells in the dermis, which are crucial for initiating immune responses. As a results, the transdermal vaccine delivery system provides a promising approach to disease control.

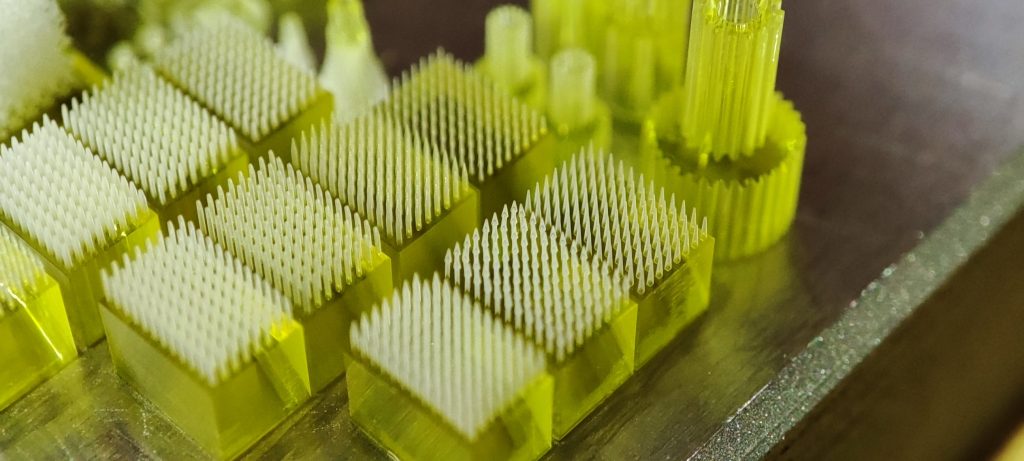

In order to improve the microneedle vaccine delivery landscape, IPFL investigated six microneedle shapes. these shapes included a circular cone, square cone, triangular cone, cylinder with a sharp tip, rectangular with a sharp tip, and arrowhead. We arranged the needles in a square array, with parameters like length and base radius defining their geometry.

There were various factors that had to be considered for the finite element model, including antigen release via diffusion, receptor-antigen binding kinetics, antigen internalisation by cells, and antigen uptake by blood vessels. Assessing these factors provided insights into how vaccines interact with the skin.

Through the investigation, it has been uncovered that the microneedle shape has a significant influence on APC activation in both the epidermis and dermis. The key findings indicated that the rectangular microneedle with a sharp tip stood out as the most efficient in vaccine delivery because of its larger surface area, that allows it to hold more antigens and activate more APCs.

The microneedles were ranked in terms of efficiency, with the rectangular microneedle with a sharp tip at the top, followed by the cylindrical microneedle with a sharp tip, square conical, arrowhead, circular conical, and triangular conical.

Ultimately, the study revealed that the distribution of coated antigen in the skin layers was affected by microneedle shape, impacting APC activation.

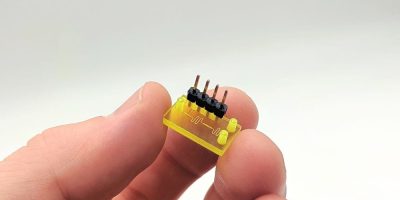

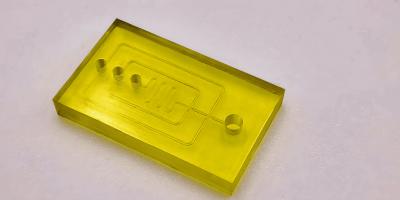

IPFL supply a precision manufacturing service as the only European service bureau running BMF 10µm and 2µm resolution 3D printing technologies.

Aiding development, prototyping and pre-production manufacture. These technologies support customer demands with intricacy and detail that was never before achievable. Products can now be proofed and launched in a far shorter timeline with greater confidence and accuracy.

Microneedle geometry plays a crucial role in revolutionising immunization practices

To conclude, microneedle geometry plays a crucial role in improving transdermal vaccine delivery efficiency. The rectangular microneedle with a sharp tip proved to be the most effective, primarily due to its larger surface area and higher antigen capacity. This research could lead to more efficient and patient-friendly vaccination methods, potentially revolutionising immunisation practices.

For more visit our BMF-focused pages

Here at IPFL, we’re able to deliver quality results via our state-of-the-art equipment. It’s not just the medical industry; we’re able to craft innovative products that have the capacity to transform any number of sectors. So, if your business could benefit from 3D-printed products, please don’t hesitate to get in touch.

We’re constantly striving to make improvements in our materials, machinery, and production, so you can rest assured that you’ll be provided with top-notch results.

We look forward to hearing from you soon and helping you develop the best products.

Ref: Noppamas Yolai, Pikkanet Suttirat, Jeerapond Leelawattanachai, Chaiwoot Boonyasiriwat & Charin Modchang (2023) Finite element analysis and optimization of microneedle arrays for transdermal vaccine delivery: comparison of coated and dissolving microneedles, Computer Methods in Biomechanics and Biomedical Engineering, 26:12, 1379-1387, DOI: 10.1080/10255842.2022.2116576