FDM’s history dates back to the late 1980s when Scott Crump invented the technology. Crump, inspired by a glue gun’s mechanism, developed the first FDM machine to create a toy frog for his daughter. Recognizing its potential, he co-founded Stratasys in 1989, and the company introduced FDM technology to the market. Since then, FDM has evolved, with advancements in materials, printer designs, and applications, playing a pivotal role in shaping the landscape of 3D printing.

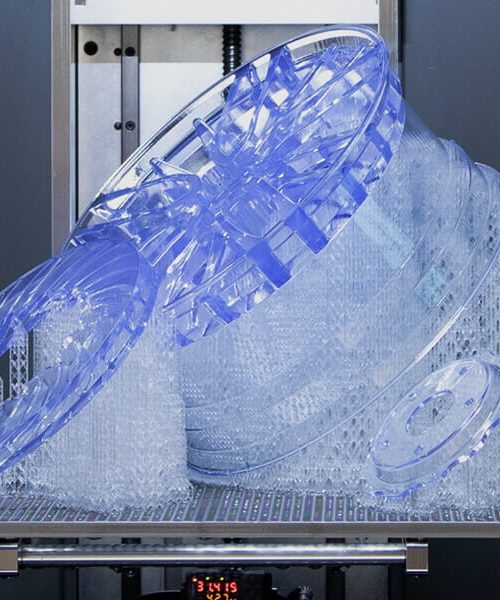

Fused Deposition Modelling (FDM) is an additive manufacturing process that constructs objects layer by layer using heated thermoplastic materials. A heated nozzle extrudes melted thermoplastic filament, which quickly solidifies upon deposition. The build platform descends after each layer, gradually building the object from the bottom up. While FDM excels in accessibility and versatility, resulting in applications like prototyping and functional parts, it can display visible layer lines and intricate detail limitations due to its layer-by-layer approach.

FDM technology uses a wide material range like PLA, ABS, PETG, PC and more. These materials offer distinct properties such as strength, flexibility, and heat resistance. Additionally, specialized variants include composite filaments infused with materials like carbon fibre or metal, enhancing object strength and functionality.

Contact us now to help you get started on your 3D Printing project using FDM ULTEM 1010