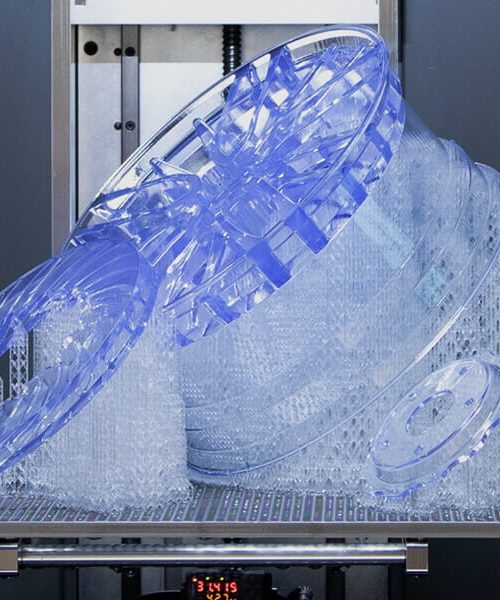

HP Multi Jet Fusion (MJF) is a recent innovation in 3D printing that provides fast production, sustainability, and unrivalled design freedom. The process, invented in 2016 by Hewlett Packard, involves the deposition of 3D printing nylon powder on a printing bed. A layer of fusing and detailing agents is then added, reflecting the shape and geometry of the part needed. The subsequent application of infrared heat fuses the powder in the required areas, and the process is repeated layer by layer until it creates the component. As the previous layer remains molten while adding the next layer, those layers bond together faster, allowing for finer detail and design. Finally, the process sheds and reuses the remaining powder for maximum sustainability and cost efficiency.

Multi Jet Fusion is now one of the most popular and cutting-edge choices to produce the most customised designs and complex lightweight parts. It is a particularly desirable option for specific components in med tech, automotive, and consumer goods, all of which benefit from the reduced time to market, cost savings and customisation afforded by MJF.

Contact us now to help you get started on your 3D Printing project using HP MJF NYLON12