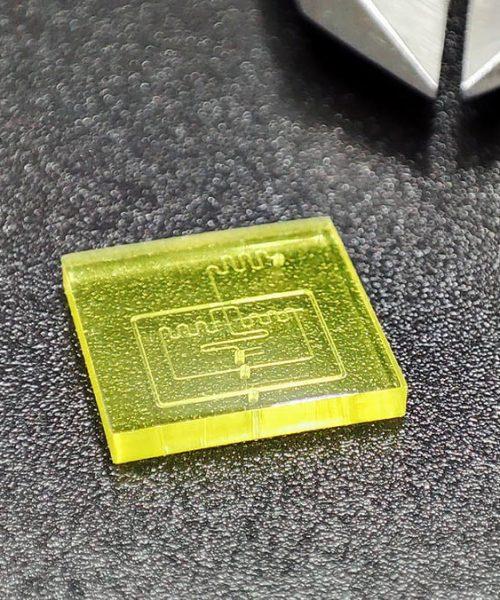

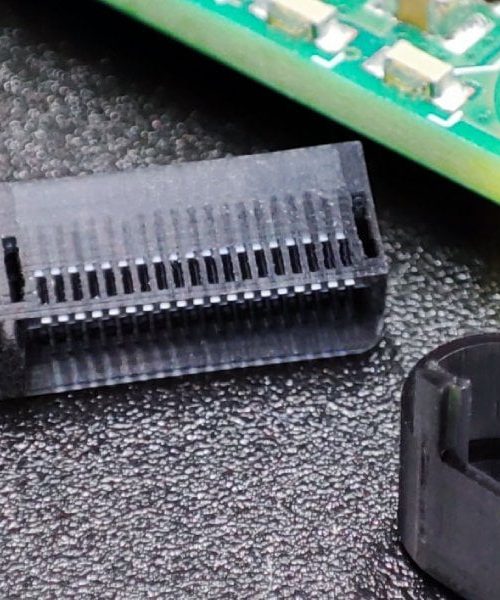

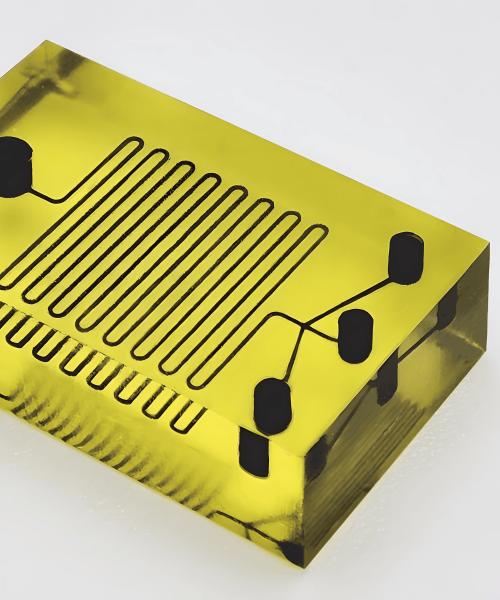

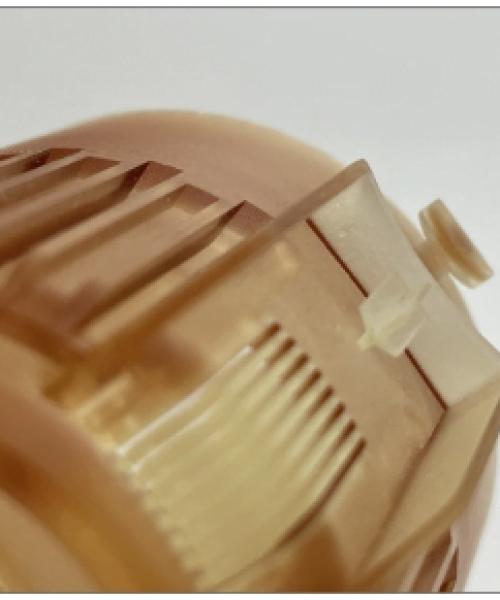

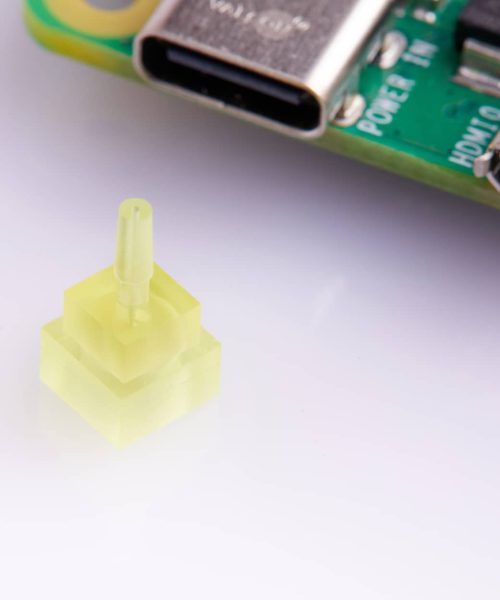

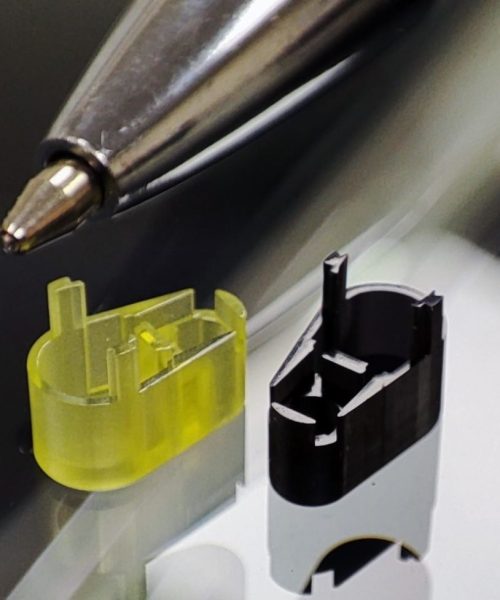

Biocompatible precision components for medtech and microfluidics

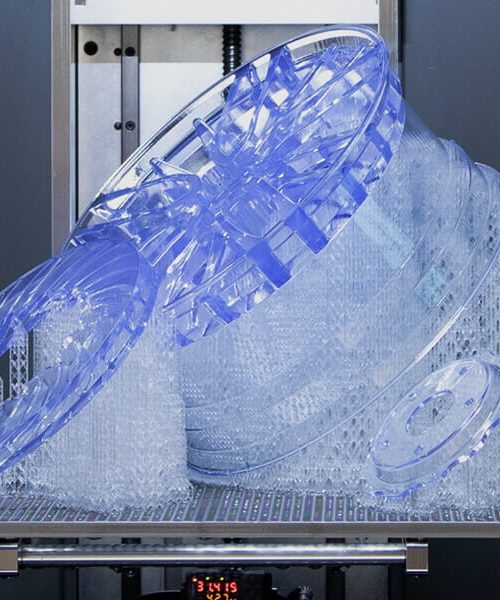

Micro stereolithography can accurately create the smallest, most geometrically complex components that are impossible to fabricate using traditional manufacturing processes.

PµSL was first developed by Professor Ikuta and Hirowatari in 1993 as a variation of common SLA 3D printing. Unlike other 3D printing technologies that use melting or extrusion, PµSL employs UV light projection to solidify liquid photopolymer resin in layers by layer.

This process lends itself to the microfabrication of unique products and intricate components with a high level of precision and surface finish. Its application spans microelectronics and medical devices such as delicately bespoke surgical stents or microfluidic channels for labs-on-a-chip devices. It can print at 10µm layers to achieve a surface polish of up to 0.4µm Ra on top surfaces and 1.5µm on sidewalls with a diverse material range including metals, plastics, and ceramics. Users can tailor the material to their application.

Contact us now to help you get started on your 3D Printing project using MICRO RG