PolyJet 3D printing, pioneered by Objet Geometries, emerged in the early 2000s as a revolutionary additive manufacturing method. Developed to surpass the limitations of conventional 3D printing it was introduced commercially in the early 2000s and quickly gained traction in diverse industries such as product design, automotive, and medicine, catering to high-detail prototypes and intricate models.

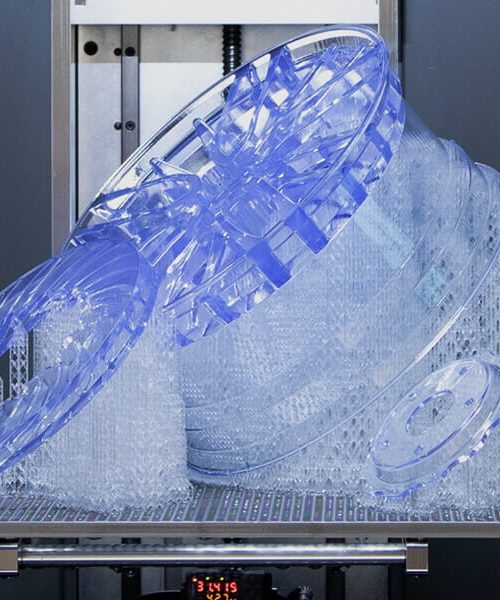

PolyJet 3D printing operates by jetting layers of liquid photopolymer resin onto a build platform. Once deposited, UV light is immediately applied to the resin, causing it to rapidly cure and solidify. This layer-by-layer process creates the final object.

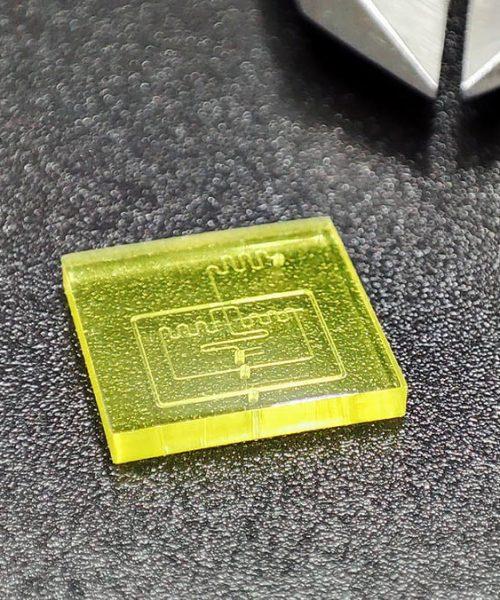

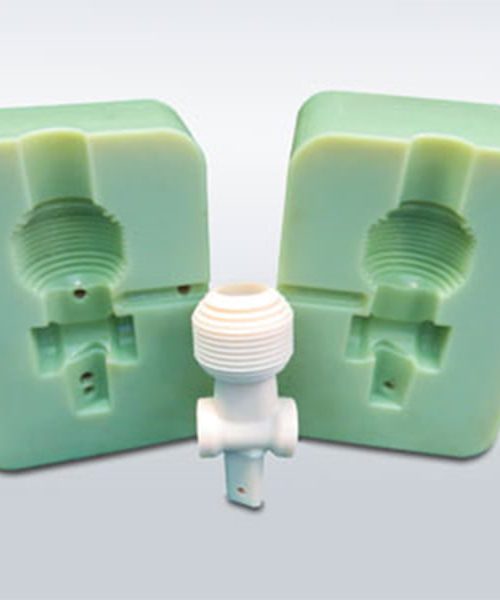

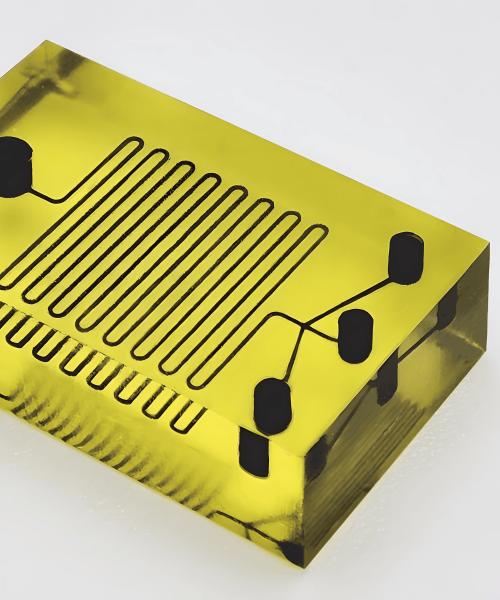

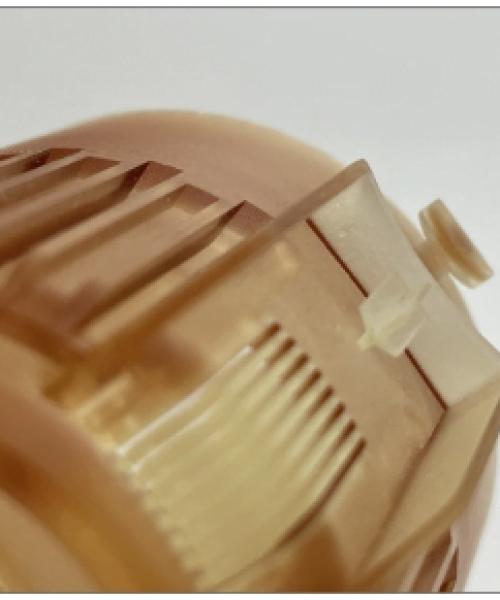

PolyJet’s unique feature lies in its ability to simultaneously jet multiple materials or resins. This enables the creation of intricate, multi-material objects within a single print run. The technology can also produce varying material properties, colours, and even transparencies within a single model.

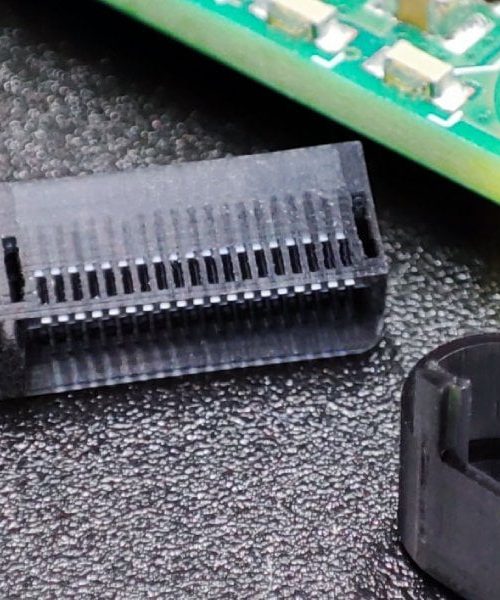

The result is highly detailed, multi-material objects with smooth surface finishes. This makes PolyJet suitable for applications such as prototyping, product design, and even some medical applications, where precision and aesthetics are paramount.

Contact us now to help you get started on your 3D Printing project using POLYJET DIGITAL ABS