High-Resolution 3D Printing - Ideal for 3D Printing for Medical Devices and Rapid Prototyping.

SLA 3D printing operates by solidifying liquid photopolymer resin layer by layer using UV light. After completion, the object is rinsed to eliminate excess resin and cured, often involving additional UV exposure, to enhance the object’s final properties.

3D print SLA has excellent precision and the ability to create intricate, smooth-surfaced objects, making it valuable for applications like rapid prototyping, dental models, and artistic designs.

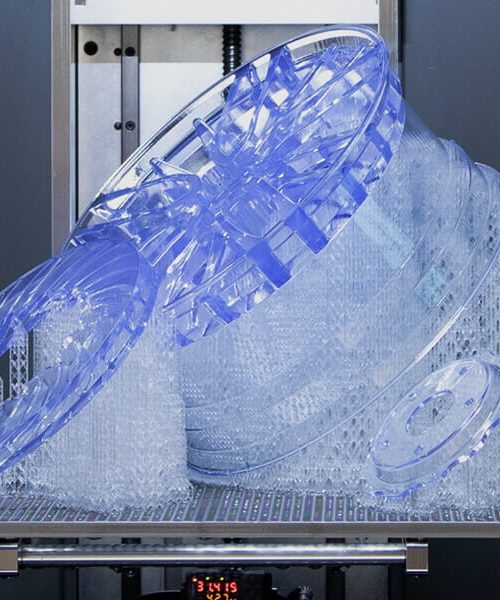

As the first NEO450s service in the UK, this brand-new SLA 3D printing service system at IPFL boasts remarkable surface quality, accuracy and detail for parts in a 450x450x400mm envelope. The exceptional part quality and production speeds can be utilised for product development, prototyping, props, rapid tooling and master patterns. The British-engineered machine, coupled with advanced software development, enables the new NEO to create complex geometries and finely detailed parts. This makes our SLA 3D printing opportunities ideal for all sorts of intricate and detailed applications, allowing you to create creative and precise artistic designs.

There is a plethora of advantages of SLA 3D printing that aid you with any project and application and our service allows you to reap all of these benefits. Some advantages of SLA 3D printing are:

Smooth surface finish– SLA printers can create parts with smooth finishes.

High detail for miniatures– SLA 3D printing can provide detailed miniatures with perfect quality.

Print complex patterns– It can accurately print complex patterns that are often challenging for other 3D printing machines.

Short print time– With 3D printing SLA, it is generally shorter as it depends on the volume, not the complexity.

Various material designs– There is a wide range of materials available for all sorts of projects.