High-Resolution SLA 3D Printing Services - Ideal for 3D Printing for Medical Devices and Rapid Prototyping

SLA 3D printing operates by solidifying liquid photopolymer resin layer by layer using UV light. After completion, the object is rinsed to eliminate excess resin and cured, often involving additional UV exposure, to enhance the object’s final properties.

3D print SLA has excellent precision and the ability to create intricate, smooth-surfaced objects, making it valuable for applications like rapid prototyping, dental models, and artistic designs.

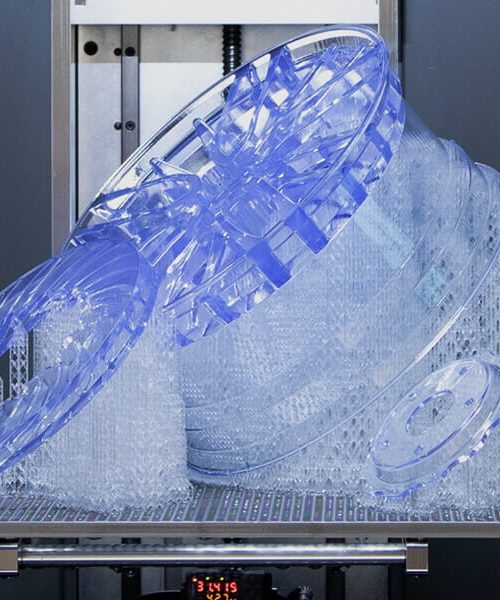

As the first NEO450s service in the UK, this brand-new SLA 3D printing service system at IPFL boasts remarkable surface quality, accuracy and detail for parts in a 450x450x400mm envelope. The exceptional part quality and production speeds can be utilised for product development, prototyping, props, rapid tooling and master patterns. The British-engineered machine, coupled with advanced software development, enables the new NEO to create complex geometries and finely detailed parts. This makes our SLA 3D printing opportunities ideal for all sorts of intricate and detailed applications, allowing you to create creative and precise artistic designs.

SLA 3D printing (Stereolithography) uses an 80µm UV laser to selectively cure photopolymer resin layer by layer, creating highly detailed plastic parts with exceptional surface finish and precision.

The process begins with a liquid resin in a tank. A UV laser traces each layer of the part, hardening the resin where needed. The build platform then moves slightly, allowing the next layer to be cured on top. This is repeated until the full part is formed.

Layer thicknesses are typically between 50–100 microns and can be adjusted to balance speed, resolution, and accuracy.

SLA 3D printing is ideal for High-resolution prototypes, Medical models and device components, Microfluidic parts and fine features, Visual models and presentation-grade parts & Complex geometries requiring smooth surfaces

With its sharp detail, tight tolerances and clear material, SLA is perfect for precision applications in medical, electronics, product design, and research sectors.

SLA (Stereolithography) 3D printing is a leading technology for producing high-resolution plastic parts with outstanding surface finish and fine detail. Using a UV laser to cure layers of liquid resin, SLA creates smooth, accurate components — ideal for both visual models and functional prototypes.

SLA 3D printing is perfect for low-volume production, engineering development, and precision applications where detail and finish matter.

Our SLA 3D printing service delivers parts that are:

Ready to Print?

Upload your CAD file to get a fast quote and see how our SLA 3D printing services can bring your design to life with unmatched precision and clarity.